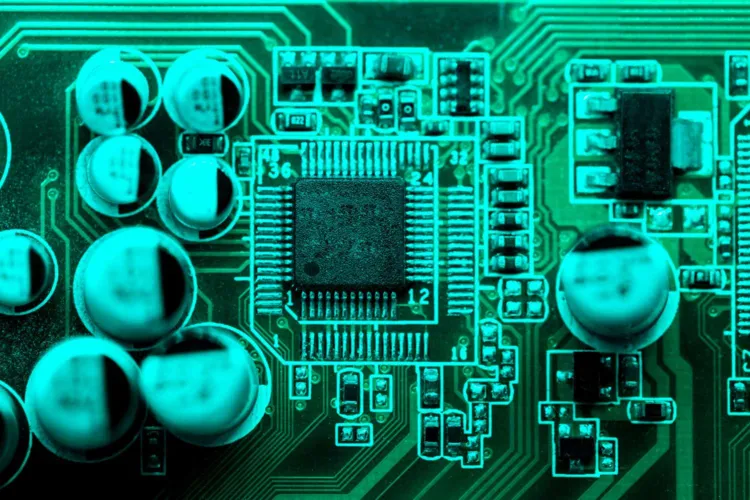

Vietnam is accelerating its shift toward smart manufacturing. With rising labor costs, global supply chain demands, and fast-moving technology, the country is investing heavily in automation, artificial intelligence (AI), and the Internet of Things (IoT). At the heart of Vietnam Smart Manufacturing Initiatives are robust government policies and public-private partnerships aimed at building a more efficient and competitive manufacturing sector.

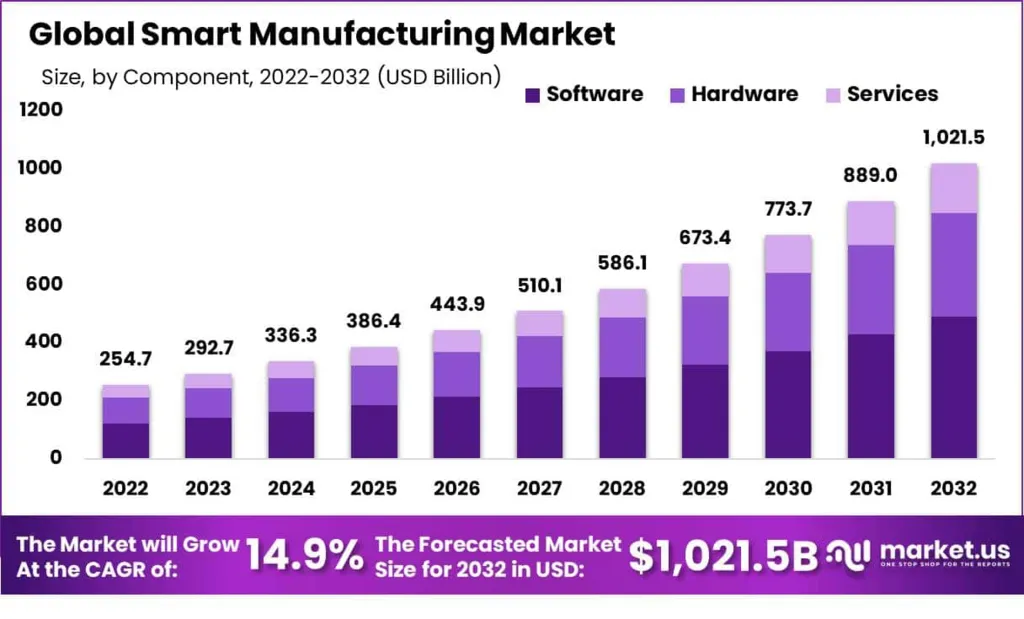

A Market Poised for Rapid Growth

The market data tells a compelling story. The Vietnam smart manufacturing market is projected to grow at a CAGR of 10.7% from 2025 to 2033. According to 6Wresearch, that growth could reach 23.4% CAGR between 2025 and 2031, while the broader Industry 4.0 market may expand by 25.7% annually. These figures show Vietnam is not only keeping pace with the global tech wave but actively shaping its future around it.

Government Strategy Leads Vietnam Smart Manufacturing Initiatives

A key driver of this growth is the Vietnamese government’s National Strategy for Industry 4.0, which outlines a clear vision through 2030. This strategy promotes the integration of smart technologies—AI, IoT, and robotics—into manufacturing. Alongside tax incentives, infrastructure upgrades, and financial support, it’s creating an ecosystem where innovation can thrive.

Read Also: Vietnam Manufacturing Supply Chain Shifts: Global Role

Success Stories: Samsung’s Smart Factory Projects

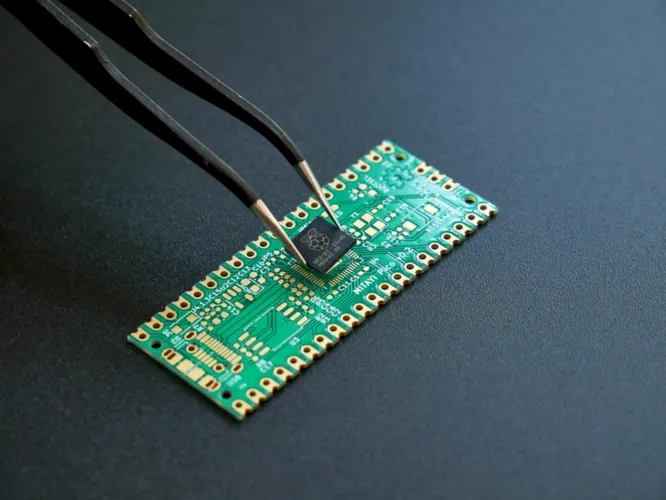

On the ground, this transformation is already producing results. One standout example is Samsung Vietnam’s “Smart Factory Development Cooperation” project, which worked with 14 local firms to reduce production lead times, improve inventory control, and introduce real-time monitoring systems. These changes not only streamlined operations but significantly boosted productivity.

In partnership with the Ministry of Industry and Trade, Samsung also launched a smart factory development initiative in Vinh Phuc province. Between 2022 and 2023, the program aimed to train 100 experts and support 50 businesses in adopting smart manufacturing systems. Training included 12-week sessions designed to help consultants gain hands-on experience in setup and operations. The goal: to help small and medium-sized enterprises (SMEs) meet global production standards and integrate into international supply chains.

Private Sector Innovation Driving Adoption

Other tech players are joining the push. Companies like Siemens, ABB, Viettel, and FPT Software are rolling out automation solutions and IoT platforms. Their involvement is expanding access to smart manufacturing tools, especially for smaller firms looking to modernize.

Read Also: Rapid Vietnam Digital Transformation Explained

Vietnam Smart Manufacturing Initiatives: Building Human Capital for Industry 4.0

Another critical part of Vietnam’s strategy is workforce development. Programs backed by government and corporate partners focus on skills training, digital literacy, and systems integration. This growing talent pool is key to making advanced technology sustainable and scalable.

Tangible Benefits of Smart Manufacturing

Smart manufacturing isn’t just about machines, but also about creating value. By adopting technologies like barcode inventory tracking and real-time defect monitoring, Vietnamese factories are achieving measurable gains in quality, efficiency, and cost control.

Vietnam Smart Manufacturing Initiatives: A Nation Embracing the Future

Vietnam Smart Manufacturing Initiatives are transforming the country’s industrial landscape. Backed by strong policy, rising investor interest, and effective partnerships, the shift toward Industry 4.0 is no longer a vision. With training programs, cutting-edge technologies, and a supportive regulatory framework in place, Vietnam is setting itself up not only to compete but to lead in the age of smart manufacturing.